by Tyler Frye

Mashing is an essential function of home brewing for the all grain brewer of either ‘Brew in a Bag’ or traditional Mashers. Since these methods do not rely on extract to achieve the pre boil wort, the brewer must make the most of his grist to get the most bang out of their grains. Most all grain brewers are familiar with the basic concepts of mashing, strike your mash at a specific temp to get your saccrification rest between 148-158, rest, lauter with a sparge. These steps are essential for achieving a high efficiency mash but with a few tips and tricks you can push your mash even further.

1.) Mash pH

The mash pH is essential for several reasons, the final wort pH will effect boil and fermentation efficiency, and the enzymes involved with saccrification have pH optimizations. Most studies indicate that a mash pH of 5.2-5.7 are sufficient for optimal alpha and beta amylase activity. While most dark roast grist bills will bring down your pH dramatically, lighter grain bills will require

water acidification to reach target pH range. Lactic acid (food grade) is readily available at 88% concentrations and I have generally found that 1ml per 4-5 gallons tap H2O will bring the pH to 6.5-6.8. Please be mindful of filtered water as it will acidify rapidly with lactic acid (Sorry Tyler Blackwelder :P). Water with a pH of 6.5-6.8 with your light grain bill will bring your pH into range. pH also plays a major role in Tannin solubility. Keeping the temp low will inhibit Tannins in your wort, more on that below.

2.) Water to grist ratio

The water to grist ratio is a measure of mash thickness. A thin mash will have a high water to grain ratio while a thick mash will have a lower water to grain ratio, think of soup vs. stew. Studies by Briggs et al (2004) indicate that a thin mash (high water to grain ration) will have higher mash efficiencies across multiple temperature ranges and will not drop temperature during the saccrification rest. Conversely, thick mashes will hold the same mash efficiency regardless to mash temp and will lose temp more easily. A thick to thin mash will generally have the ratios of 2.57 L/Kg to 5 L/Kg respectively or 0.78 qt/Lb to 2.4 qt/Lb. I generally shoot somewhere on the middle side at 1.55 qt/Lb, while most homebrew literature suggests 1.8 qt/Lb.

3) Diastatic Power and grains

The enzymes that convert starches in grains are measured by diastatic power, grains with a high diastatic power have a greater ability to convert starches. Diastatic comes from the fact that

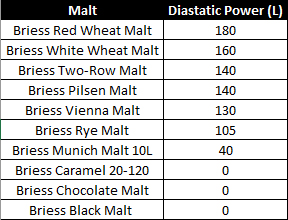

amylase enzymes belong to a larger class on enzymes called diastases, enzymes that convert starches of many forms. Diastatic power increase with value the higher the enzyme efficiency. The higher your diastitc power the more efficient your mash will be. Some classic malt styles have very low diastaic values while base malts tend to be higher (see Fig 1.).

Malts like Munic will have poor conversion in the mash without malts like Wheat, Pilsner or Vienna to boost enzyme activity. A few years ago the home brew club did a “Smash off” where each brewer did one malt and one hop. I did 10 lbs of Munich and some Tettnanger, my mash efficiency was one of the lowest I had ever recorded. Most good Oktoberfest and Dunkel recipes utilize Pilsner or Vienna to overcome the poor enzyme activity. Adding Wheat can also boost your mash efficiency, just make sure it has been malted.

4) Slow down your Lauter

The brew day for all grain can be quite long. Sitting around for a long lauter can be even more painful. But this is one of those unique steps where you can have a beer and watch it all go down, literally. The Lauter is simply the transfer of wort out of the mash tun to the boil kettle. Brew in the bag, partial mashes and extract brewers need not worry so much about this step, but for all of you tapping those modified Igloo coolers for that sweet sweet nectar take your time with that transfer. An hour to hour and a half should be sufficient

for good mash efficiencies to the mid 80%s. In the past, my own experience has shown that a rushed lauter will get me down to the high 60 to mid 70%s. I try to shoot for 75-90min lauter.

5) Good Sparge

One way to really grab those sugars is to rinse your mash with nice hot and acidulated water. One culprit that can affect your mash efficiency is Tannin solubility. As Tannin starts to dissolve in your mash it becomes harder for sugars to be soluble. To prevent this keep Tannins out by increasing acidity and keeping temp below 175F. Tannins will have a hard fight getting into your wort if you can beep the runnings pH below 6 and keep temp from getting to high.

Another factor to dissolve and rinse those sugars is to keep the temp high in your sparge. If the temp gets too high then you will start to dissolve Tannins off the malt husks, conversely sugar solubility is temp dependent. 168F-172F tends to be a happy temp range that keeps sugars in and Tannins out. Also, with regard to sparging, there are multiple methods.

The three most common are No-sparge, batch sparge and fly sparge. No-sparge involves mashing with all your water or just grabbing the first runnings and filling up with water. Batch sparge involves infusing your whole mash at once and mixing both runnings. Fly sparging involves adding water to the top of the grain bed of your mash as you lauter. Of the three fly sparge is considered to be the most efficient, batch sparge being the second most efficient, while No-sparge generally requires a 25% malt increase of your total mash to compensate for how poorly the sugar extraction is. A fly sparge also has the added bonus of constantly keeping your mash bed wet which prevents oxidation of tannins and polyphenols.

Thanks for reading and keep on brewing!

Nice article Tyler.